A Power Budget is an ordered list of your project's power needs. At some point, you must choose a power supply to meet those needs. Finding Current capacity for each Voltage is your goal. Without enough power supply capacity, projects can fail or exhibit strange symptoms. Current capacity is stated in Units of milliAmps or Amps depending on the power involved.

A written budget helps you find the correct capacity power supply. Once you locate suitable candidates, you can check size, weight, wiring, and cost from product listings. This way you know crucial details before purchase. You can buy -- or make project changes based on what you learned.

Writing the Power Budget

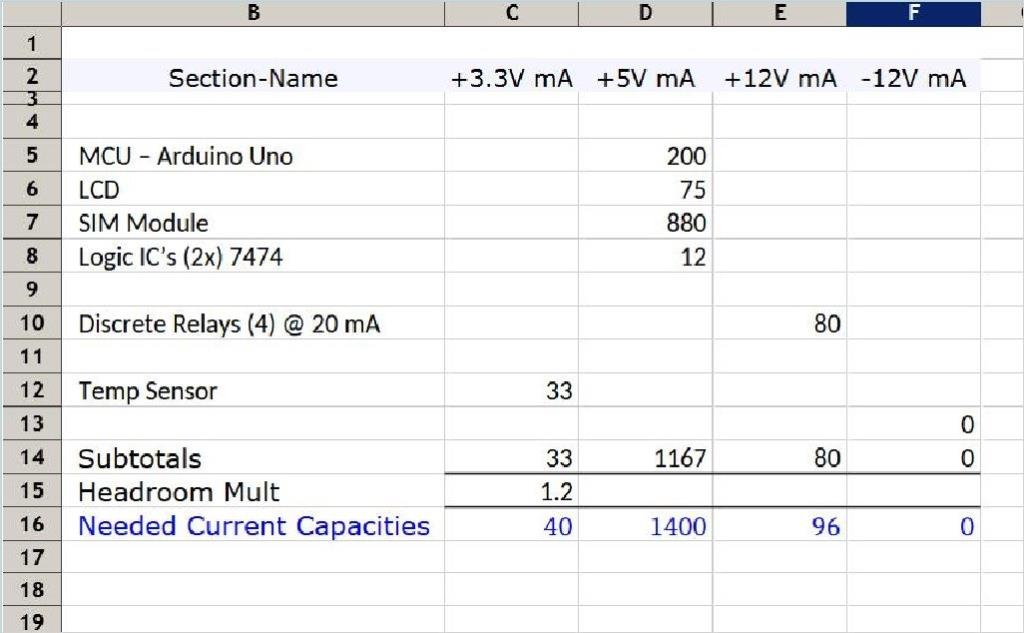

Start by listing all required Voltage feeds. Then, add up Current requirements for each Voltage. You can organize this in a spreadsheet form, where;

- Columns represent each Voltage

- Rows show the section names and their corresponding Current values

Next add the Currents for each Voltage column. We note each subtotal Current and add a 20% to 50% headroom multiplier beneath. At bottom, increased Current sums are derived by multiplying each subtotal by the headroom multiplier.

The entire process may take 20 minutes to several hours. If you have the needed information, it can go quickly. See next image...

Finding Section Currents

Divide your project into smaller sections that seem logical. Then determine each section's Current info. Its easy to get module and MCU Currents from datasheets. But other areas with discrete components may challenge your thinking. Maybe its a transistor or a relay that eats mA when actuated. How can you get the correct Current values?

Try this;

- ON-OFF Sections: With items that consume Current at varying intervals, assume an always-ON situation. This ensures your PSU can accommodate needed Current when the ON time comes. Use this approach for currents used by LED's, Relays, Solenoids, Motors, Fans, buzzers, etc.

- MODULES: When using purchased modules, get Current data from documentation or datasheet. Typical examples may include; a Real Time Clock, MCU, RF Transceiver, SD, GPS, LCD, etc. If current data isn't available, you can always measure the Module's Current with a series multimeter in current-mode. If power info is written in a range, use the high end value.

- DISCRETES: Transistors and MOSFETs are often used as switches. The switched Current is already accounted for by the section-current (or load-current) being controlled. A datasheet should reveal any Current sensors consume. LED's usually have datasheets (often 10-20 mA per color). Super bright LEDs require a datasheet to find their specific Current demand.

- EXTERNAL FEEDS: If power gets routed out to external devices, note that mA requirement as well. Treat it as another (Always ON) section in your break-down analysis. Even if its an auxiliary feed, assume constant use -- add the Current value into your power-budget.

Power Budget Headroom

We always need extra capacity. Its essential for long project life and safety. Some folks use 20% as a rule of thumb. Others choose more. Without extra headroom, your supply runs at full capacity all the time! That's bad for long term reliability (and perhaps safety).

In our budget, we'll have a capacity multiplier to derive final-totals from subtotals. This is our headroom allowance. Use at least 20% (multiplier=1.2). More headroom is better but impacts size and cost.

Power Budget and Battery Capacity

You may think battery power is the way to go. But you're not sure how much battery you need. Battery Capacity is rated in Amps-times-hours (Amp-hours). An example is a 10 Ah battery is expected to supply 1-Amp for 10 hours -OR- 10-Amps for 1 hour. This is almost never how things work out. But its a handy way to estimate Project operating-time.

A usual aspect of battery Capacity calculation is deciding how many hours of run-time is expected of the battery. This requires guesstimating your project's Average hourly Current. This can be tricky with electronics that varies its Current demand (Audio volume, motor ON-OFF times, etc).

- I suggest using your power budget Total-Current for this calculation. Divide it into the battery Amp-hour rating for a decent estimation of operational run-time.

- However, there's a catch! Battery manufacturers often state Ah Capacity on a condition of -typical- Current draw! This typical value may be well below what your budget calls out. Be Careful to check on this! If you draw Current above the -typical- rating, your battery won't live up to its Amp-hour rating!

- I NEVER USE rechargeable batteries in a DIY (or any home made project) due to Safety, Liability and Insurance issues.

As an example, a project with an average hourly Current of 728 mA can be expected to run approximately (2000/728 =2.74 Hours ) using a battery with a rated capacity of 2000 mA-hours. This assumes the battery is rated to handle 728 mA as a typical allowed discharge rate.

Power Supply Shopping

Now you know your Power Budget numbers regarding Currents and Voltage. Sometimes you can't find a PSU with the exact multiple Voltages with enough capacity for (1 or more) needed Currents. A work-around is buy discrete supplies that deliver adequate Current at each wanted Voltage. Be sure you consider impact on mounting space and wiring!

As you find PSU candidates, take note of Price, Dimensions, Weight and Wiring needs. If you choose a Switch-mode type, pay attention to ripple (AC voltage noise) that can appear on DC outputs. Switchers are smaller but can be noisy. Linear PSU's are larger with generally clean DC.

NOTE: Wall wart type power supplies may overstate Current capacity without warning of possible Voltage drop and ripple increase. Be very careful choosing these supplies for your build! You may see a rating of 2 Amps (2000 mA) only to find at 1000 mA the Voltage drops 10%.

In Summary

We've seen how to write a Project Power Budget by separating Voltage feeds and summing section Currents. We've covered methods for finding each section's Current. Adding headroom ensures the supply doesn't run at full Current capacity. Knowing budget totals, we shop for PSU candidates with confidence. PSU size, weight, and cost is found in sales listings. Using discrete supplies helps fill power budget needs when a do-all PSU isn't available.

With a Power Supply of the correct capacity, your project should run without mishap. An under capacity situation can lead to problems. Play it safe and use the correct Power Supply for your build.

Lee